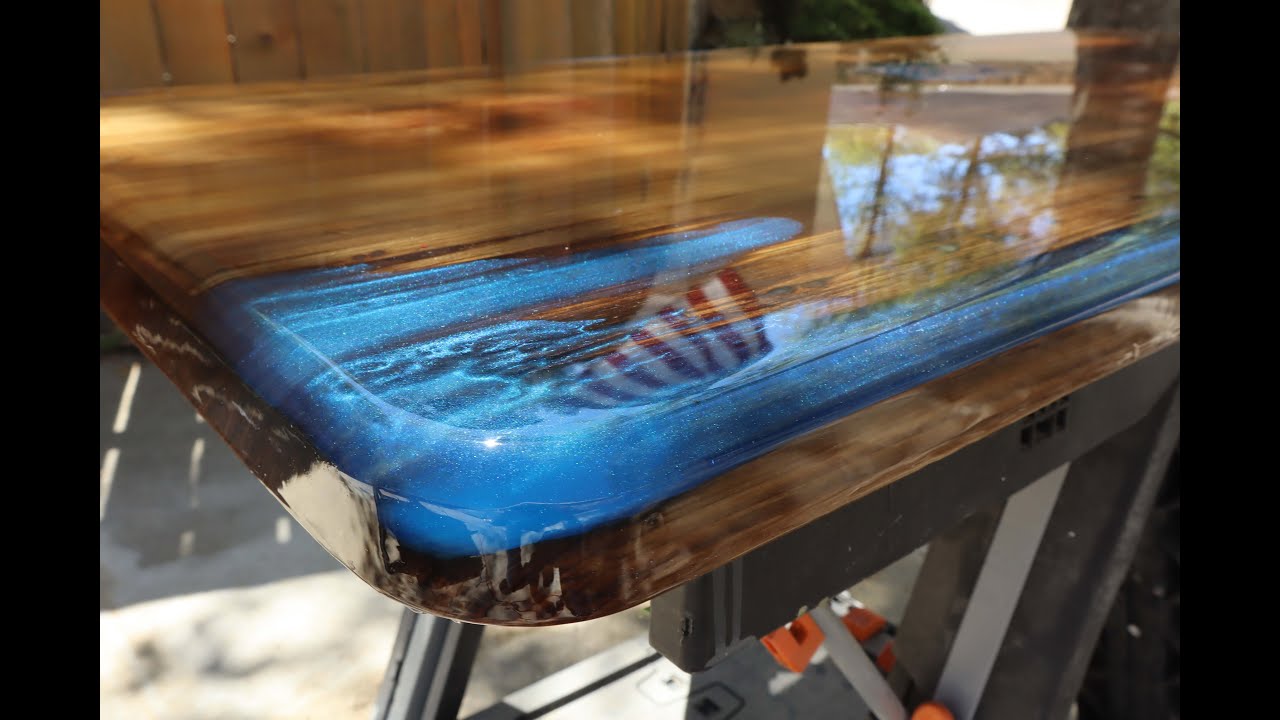

Then we took the table indoors and hit it with some Rubio Monocoat which is an oil that locks into the wood and gives it some incredible shine. Use a high-speed motor on your buffer to speed up this process so that you dont wear yourself out.

Wood And Resin Glow Table Diy Plans Diy Epoxyresinglow Glow Plans Resin Table Wood Glow Table Diy Plans Epoxy Resin Table

Always start small and slowly increase the grit of your sandpaper.

. Use the yellow scraper and the heat gun to move the epoxy around help spread it evenly and pop any air bubbles. Work from top to bottom in straight lines. I currently use each of these finishes on the custom made furniture and art pieces I make for my clientsBe sure to.

But if you want to make your floor look even better there are some easy things that you can do to make it shine. If your epoxy resin has cured but can be dented with a fingernail or softens with body heat. Dip and wring a soft cloth in the product and rub off the stains by hand.

First sand down any rough spots or low spots with a hand sander or orbital buffer using 80 grit sandpaper. Pay particular attention to any visible scratches and apply extra pressure to these areas. Use a microfiber cloth to rub the compound into a small piece of resin.

Use a plastic spreader to help smooth the vertical edges. The product will come off on the cloth as you go along and leave behind a shiny finish. If there are still spots left you might want to invest in an all-purpose surface cleaner.

Pour mixed epoxy slowly onto the table top distributing it across the top as you pour. To make resin shiny after sanding apply polish with a polishing pad. With wet sanding youre carefully sanding from coarse grit to grit going from 120 to 1000 in circular movements either by hand or with an orbital sander.

Then mix one part liquid detergent with two parts warm water and apply it to the surface using a clean white cloth. Be sure to wash off all the sawdust and let your piece dry before applying a coating. I make cuttingserving boards with resin in them and put salad bowl finish or mineral oil over the.

These finishes work great for new epoxy table tops epoxy resin artwork and to resurface existing table tops. If youre looking for a classy elegant finish to your epoxy dining tables we highly recommend you try a beveled edge. Allow the mixed epoxy to flow over the sides.

Next preheat your epoxy especially during the colder months. Here polishing epoxy resin helps to give the final result that certain. When getting up to the highest grit you may find your epoxy is polished enough to your likening.

In this HT post I show you 4 finishes I use for epoxy wood projects. To clean and shine your epoxy floor rinse the surface with warm water. To ensure you get a perfectly smooth finish follow these tips.

Thoroughly clean the epoxy resin table using a mild household cleaner and let it completely dry Mix two-part epoxy resin until its completely blended Use a small craft stick to fill in the scratch or chip as much as possible Let it completely dry Scrape off excess epoxy resin using a dull razor blade at an angle along the repaired scratch. Use firm pressure while moving the cloth in circular motions to polish the resin piece. Apply a small amount of polishing compound to the countertop surface using a microfibre soft cloth Work the compound into the worktop in a circular motion Dont over work the compound this will avoid bringing the surface to a high shine then wipe away any excess polishing compound and visually check no spots have been left matt.

Clean the epoxy with hot water and dry it using a squeegee. Glossy Finish UVPoxy can be used for a glossy finish on your epoxy table. Buffing on the other hand acts as more of a filler than a remover like sanding.

Make sure the temperature of your workspace is between 70 and 80F the ideal room temperature for a smooth curing process. Additionally I show you how to apply each finish how I decide which to use. Thats enough to give the floor a shiny look.

You can do this by placing your epoxy in front of a space heater for about 30 to 40 minutes just to make sure that that epoxy loosens up and is easy to work with.

Project Center Resin Jewelry Making Resin Crafts Diy Resin Projects

Coating Your Tabletops With Epoxy Is The Best Way To Protect Them While Giving A Shiny Finish By Using The Id Diy Resin Table Epoxy Wood Table Food Safe Epoxy

Glow In The Dark Live Edge Cedar Coffee Table Top Coated With Rust Oleum Parks Super Glaze Bar Top Coating I Resin Furniture Woodworking With Resin Wood Resin

Epoxy Resin Table Tutorial How To Build Your Own River Table Wood Resin Table Epoxy Resin Table Resin Table

How To Sand And Polish Epoxy Resin Diy Resin And Wood Diy Resin Diy Epoxy Resin

Made To Order Custom Ultra Clear Epoxy Table Epoxy Wood Resin Etsy In 2022 Wood Dining Table Rustic Diy Resin Wood Table Dining Table

Pin On Black Walnut River Table

3 How To Sand And Polish Epoxy Resin Youtube Resin Furniture Wood Resin Table Resin Countertops

How To Polish Resin Diy Resin Wood Table Resin And Wood Diy Resin Diy

Epoxy Resin River Table Glowpowder 20171016 77 Epoxy Resin Wood Epoxy Resin Table Glow Table

4 Best Finishes For Epoxy Table Top Updated 2022 Video Video Wood Resin Table Resin Furniture Epoxy Wood Table

Made To Order Custom Ultra Clear Epoxy Table Epoxy Wood Resin Etsy Resin Table Epoxy Wood Table Epoxy Resin Wood

How To Make A River Table Using Clear Epoxy Casting Resin And Reclaimed Cedar Wood Youtube Woodworkyoutube Live Edge Wood Resin Furniture Epoxy Resin Table